The Ultimate Guide to CNC Machining Manufacturers: Services, Benefits, and Choosing the Right One

When it comes to precision manufacturing, CNC machining manufacturers play a crucial role in turning designs into high-quality, functional parts. Whether you're in the automotive, aerospace, or consumer goods industry, selecting the right CNC machining service can significantly impact your project's success. In this guide, we'll dive into what CNC machining is, the services offered by manufacturers, the benefits, and key factors to consider when choosing the best provider for your needs.

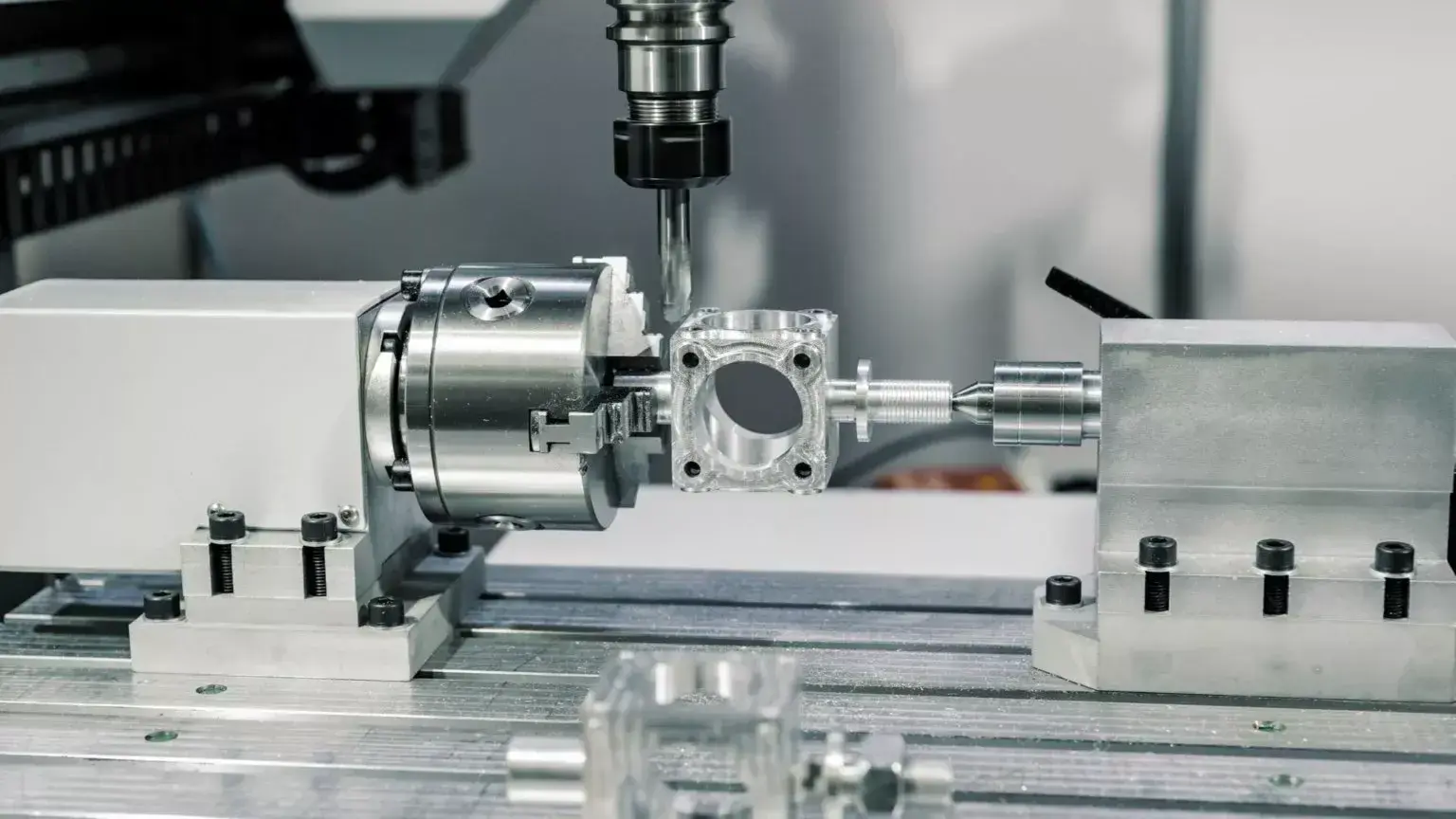

What is CNC Machining?

CNC machining (Computer Numerical Control) refers to the use of computer-controlled machines to automate the process of cutting, drilling, milling, and shaping materials into precise parts. These machines can work with various materials, including metals, plastics, and composites, and are essential for industries requiring tight tolerances and high-quality finishes.

CNC Machining Services Offered by Manufacturers

| CNC Machining Service | Description | Applications |

|---|---|---|

| CNC Milling | Uses rotating cutters to remove material from a workpiece. | Automotive parts, medical devices, aerospace components. |

| CNC Turning | Rotating the workpiece while the tool is fed into it to cut material. | Small to medium-sized parts, custom components. |

| CNC Grinding | Utilizes rotating wheels to remove small amounts of material. | High-precision parts, tool sharpening. |

| CNC Laser Cutting | Uses a laser beam to cut materials with high precision. | Sheet metal parts, custom shapes, and designs. |

| CNC Electrical Discharge Machining (EDM) | Uses electrical sparks to remove material. | Complex geometries, intricate shapes, small parts. |

| CNC Waterjet Cutting | Uses high-pressure water jets to cut materials. | Cutting hard metals, glass, ceramics. |

| Additive Manufacturing (3D Printing) | CNC combined with 3D printing for rapid prototyping. | Prototypes, custom parts with complex shapes. |

Benefits of CNC Machining Services

CNC machining offers several key advantages for manufacturers:

- Precision & AccuracyCNC machines can achieve incredibly tight tolerances, ensuring that parts fit perfectly and meet the required specifications.

- Cost-EfficiencyWhile the initial setup cost can be higher, CNC machining reduces material waste and labor costs, ultimately leading to lower production costs.

- Complex GeometriesCNC machining can produce intricate designs and complex shapes that would be difficult or impossible to achieve with manual methods.

- Consistency & RepeatabilityOnce programmed, CNC machines can produce thousands of identical parts with minimal variation, ensuring high-quality results every time.

- SpeedCNC machines can work faster than manual labor, reducing production time and improving overall efficiency.

Factors to Consider When Choosing a CNC Machining Manufacturer

When selecting a CNC machining provider, it's important to consider the following factors to ensure you partner with the right manufacturer for your project.

1. Experience and Expertise

- Why It Matters: Experienced manufacturers are better equipped to handle complex projects and unexpected challenges.

- What to Look For: Review the manufacturer's portfolio or ask for case studies to understand their expertise in your specific industry.

2. Range of Services

- Why It Matters: A manufacturer offering a variety of services can handle all your needs, from prototyping to mass production.

- What to Look For: Ensure they offer the specific CNC services required for your project (e.g., milling, turning, laser cutting).

3. Quality Control and Certifications

- Why It Matters: Maintaining high-quality standards ensures that parts meet the necessary specifications and function properly.

- What to Look For: Check if the manufacturer has certifications like ISO 9001, which indicates adherence to international quality standards.

4. Technology and Equipment

- Why It Matters: Advanced machines and tools can handle more complex materials and designs.

- What to Look For: Ensure the provider uses modern CNC machines capable of working with a wide range of materials and intricate designs.

5. Lead Time and Delivery

- Why It Matters: Fast turnaround times are critical for meeting deadlines and keeping projects on schedule.

- What to Look For: Inquire about lead times and how the manufacturer handles rush orders or tight schedules.

6. Cost-Effectiveness

- Why It Matters: Budget-friendly services ensure that your project remains within financial constraints without compromising on quality.

- What to Look For: Request detailed quotes and compare prices from different manufacturers to ensure you are getting the best value.

7. Customer Support

- Why It Matters: Efficient customer support can help resolve issues quickly and ensure a smooth manufacturing process.

- What to Look For: Choose a provider that offers clear communication and responsive support throughout the project.

Conclusion: Choosing the Right CNC Machining Manufacturer

Selecting the right CNC machining manufacturer is essential to ensuring your project is completed on time, within budget, and with the precision and quality you need. By considering factors such as experience, range of services, quality control, technology, lead times, cost, and customer support, you can find a manufacturer that meets your needs and helps bring your ideas to life. Whether you're looking for prototyping, small batch production, or large-scale manufacturing, the right CNC machining service will be a key factor in the success of your project.

Explore

The Ultimate Guide to Precision Machining: Techniques, Benefits, and Applications

The Ultimate Guide to the Best Credit Card Bonus Offers: Which One Is Right for You?

2025 List of Top 15 PCB Manufacturers in the USA for Your Project

Top 10 Clothing Manufacturers in the USA: Leading the Fashion Industry

Cloud ERP vs. On-Premise ERP: Which One Is Right for You?

Top 10 Data Analytics Platforms in 2025: Which One Is Right for You?

Top 10 Concrete Driveway Repair Companies Near You: How to Choose the Best One

Best Valentine's Day Gifts for 2025: Unique Ideas for Your Loved One