Sheet Metal Fabrication Services: How to Find the Right Provider for Your Needs

When it comes to custom metal parts and designs, sheet metal fabrication services are essential. Whether you're in need of prototypes, components for industrial equipment, or unique designs for personal projects, finding the right sheet metal fabrication provider is key to ensuring quality and precision. In this guide, we’ll explore the factors you need to consider and how to choose the perfect sheet metal fabricator for your needs.

Understanding Sheet Metal Fabrication

Sheet metal fabrication involves processes like cutting, bending, welding, and assembling sheet metal into various shapes and sizes. These services are used across industries such as automotive, aerospace, construction, and electronics. With the growing demand for high-quality metal products, it's crucial to select a reliable fabrication provider that meets your specific requirements.

Key Factors to Consider When Choosing a Sheet Metal Fabrication Provider

There are several factors that influence the decision-making process when choosing a sheet metal fabrication service. Here are the most important ones:

| Factors to Consider | Why They Matter |

|---|---|

| Experience and Expertise | A fabricator with years of experience will ensure precision and high-quality results. |

| Technology and Equipment | Advanced equipment like CNC machines and laser cutters improve efficiency and accuracy. |

| Customization Capabilities | A flexible provider will offer tailor-made solutions that meet your exact specifications. |

| Material Options | Ensure the provider has a variety of metals (e.g., steel, aluminum) to suit your project needs. |

| Lead Time | A reliable provider should offer realistic delivery times based on the complexity of the project. |

| Cost | Competitive pricing is important, but quality should never be sacrificed for a cheaper quote. |

| Reputation and Reviews | Positive customer reviews and industry reputation can guide you towards the best provider. |

| Customer Service | Good communication and customer support are essential for successful project completion. |

Types of Sheet Metal Fabrication Processes

Understanding the different sheet metal fabrication processes will help you select a provider that can meet your needs. Below are some of the most common processes used:

| Fabrication Process | Description |

|---|---|

| Laser Cutting | Uses high-powered lasers to cut precise shapes from sheet metal. |

| CNC Punching | Uses computer-controlled machines to punch holes or shapes into metal sheets. |

| Bending | Uses press brakes to bend sheets into specific angles and shapes. |

| Welding | Joins metal parts by heating them to their melting point and fusing them together. |

| Metal Stamping | Involves pressing sheets of metal into a die to create complex shapes. |

| Finishing | Includes polishing, coating, or other processes to refine the final product. |

How to Evaluate the Right Provider for Your Project

Now that you know what to look for in a sheet metal fabrication provider, the next step is evaluating potential companies. Consider these tips when narrowing down your options:

- Request Samples – Ask for sample projects or past work to gauge the quality of their fabrication.

- Review Certifications – Check if they have industry certifications, such as ISO 9001, which demonstrate their commitment to quality.

- Request Quotes – Get detailed quotes from multiple providers to compare costs, timelines, and quality.

- Check References – Speak to past clients to understand their experience and satisfaction with the service.

- Visit the Facility – If possible, visit the provider’s shop to inspect their equipment, capabilities, and overall operation.

Why Sheet Metal Fabrication is Critical for Your Business

Choosing the right sheet metal fabrication company can significantly affect the success of your project. Whether you're in the construction industry, automotive manufacturing, or electronics, high-quality fabricated metal parts are often the backbone of your product or service. Therefore, partnering with an experienced, well-equipped, and reputable sheet metal fabricator will ensure your components are produced efficiently and with the necessary precision.

Conclusion

Finding the right sheet metal fabrication services for your needs requires careful research and consideration of factors like experience, technology, and customer support. By evaluating the options and understanding the processes, you can ensure that your project meets the required standards of quality and precision.

Remember that the best sheet metal fabricator will not only deliver excellent results but also provide a collaborative and transparent process that keeps your project on track.

Explore

Top Injection Molding Services: Choosing the Right Provider for Your Project

Structured Settlement Annuity Companies: A Guide to Choosing the Right Provider

How to Choose the Right Hair Growth Serum for Your Hair Type and Needs

How to Choose the Right Marketing Consultant for Your Business Needs

Choosing the Right Food Packaging Equipment for Your Business Needs

Choosing the Right Sewer Camera and Locator for Your Plumbing Needs

Private Jet Charter Services: Finding the Best Options for Your Travel Needs

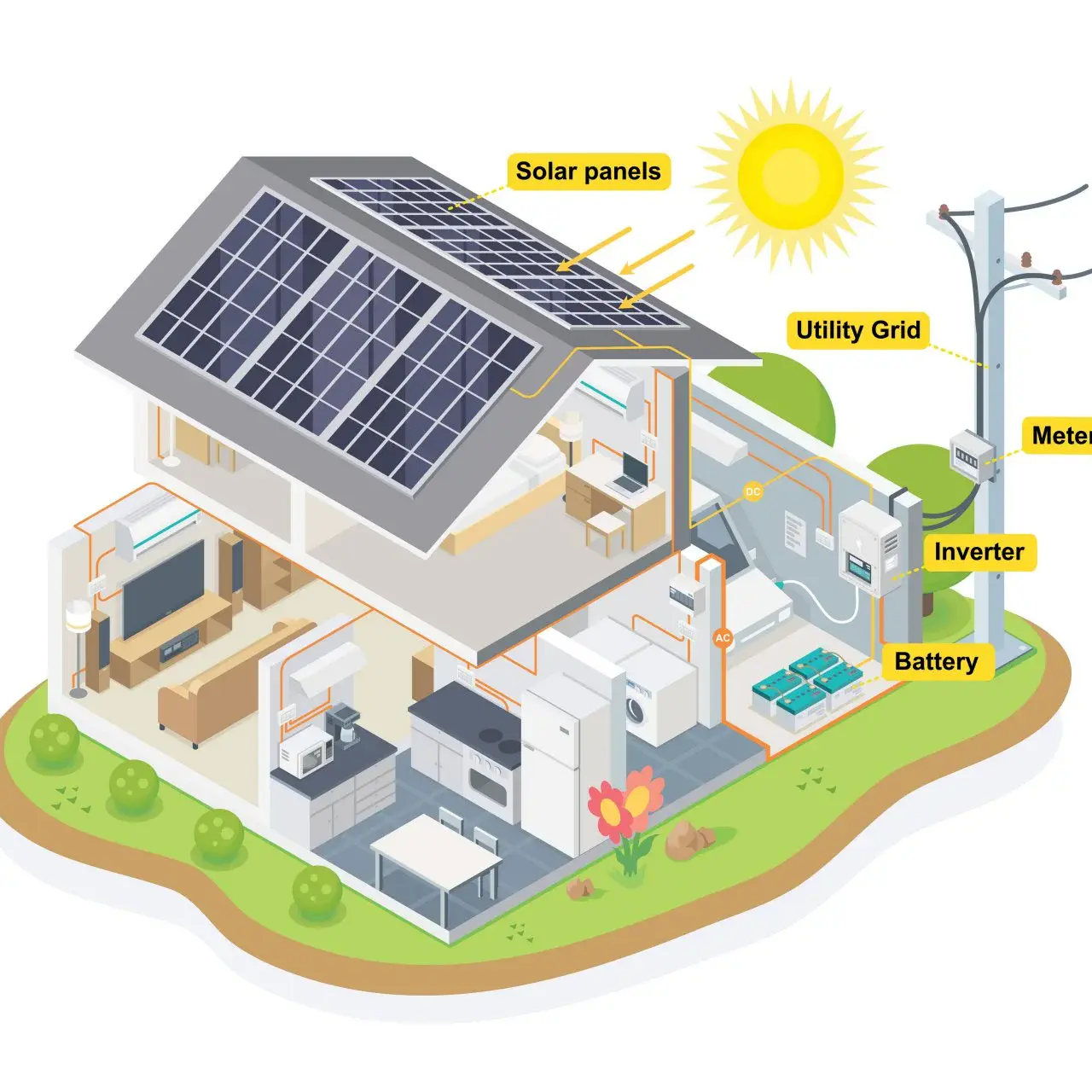

How to Choose the Best Home Solar System for Your Needs: A Complete Guide